PT Matahari Sinar Bahagia specializes in the export of high-quality coconut fiber. Trusted by international partners for sustainable, durable, and eco-friendly solutions.

PT Matahari Sinar Bahagia is a leading manufacturer and exporter of premium-grade coconut fiber (cocofiber) from Indonesia.

Our production facility ensures high tensile strength, low moisture content, and consistent fiber length – making our products ideal for industrial applications such as mattresses, erosion control, and automotive components.

We prioritize clean processing, global quality standards, and punctual delivery for our international buyers.

We export high-quality cocofiber to clients across Asia, Europe, and the Middle East.

Our manufacturing base near key ports enables fast access to global trade routes.

We ensure consistent delivery and product quality to meet your business deadlines.

We export high-quality cocofiber to clients across Asia, Europe, and the Middle East.

Our manufacturing base near key ports enables fast access to global trade routes.

We ensure consistent delivery and product quality to meet your business deadlines.

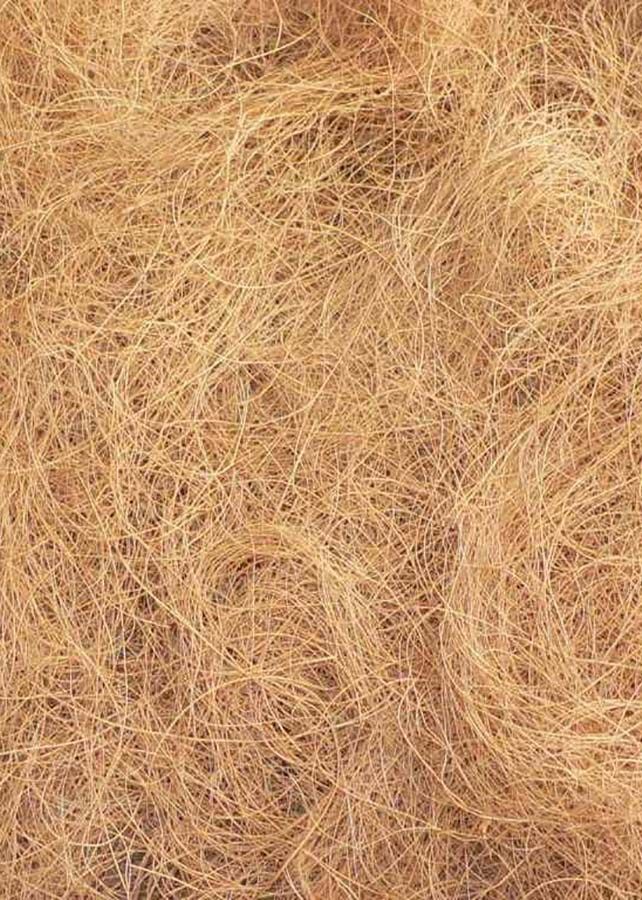

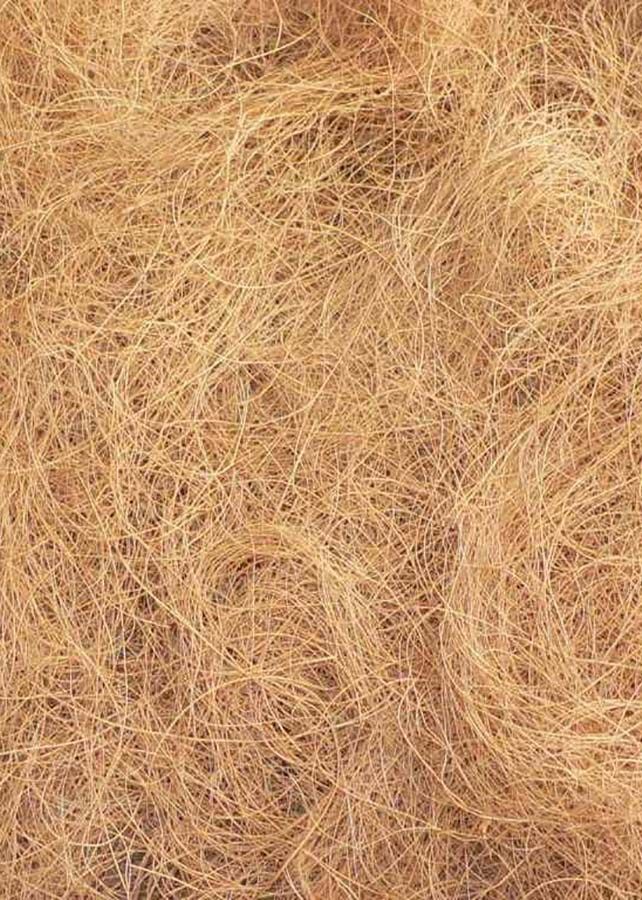

Made from coconut husk, our Cocofiber offers high tensile strength and durability. Perfect for mattresses, erosion control, and various industrial applications.

Made from high-quality coconut husk, our cocofiber offers exceptional tensile strength, elasticity, and durability.

Dimensions : 110cm x 70cm x 40cm

Weight : 90kg – 100kg (bales)

Colors : golden yellow / brown

Humidity level : 11% – 15%

Stiff and resilient natural bristles ideal for brooms, brushes, and other cleaning tools. Eco-friendly and strong, trusted by manufacturers worldwide.

Stiff and resilient natural bristles ideal for brooms, brushes, and other cleaning tools. Eco-friendly and strong, trusted by manufacturers worldwide.

Dimensions : Custom sizes (based on buyer request)

Weight : Varies per packaging

Colors : golden yellow / brown

Humidity level : 11% – 15%

A natural growing medium made from coconut husk dust. Excellent water retention, aeration, and used widely in horticulture, hydroponics, and soil improvement.

A natural growing medium made from coconut husk dust. Excellent water retention, aeration, and used widely in horticulture, hydroponics, and soil improvement.

Dimensions : 110cm x 70cm x 40cm

Weight : 90kg – 100kg (bales)

Colors : golden yellow / brown

Humidity level : 11% – 15%

Made from coconut husk, our Cocofiber offers high tensile strength and durability. Perfect for mattresses, erosion control, and various industrial applications.

Made from high-quality coconut husk, our cocofiber offers exceptional tensile strength, elasticity, and durability.

Dimensions : 110cm x 70cm x 40cm

Weight : 90kg – 100kg (bales)

Colors : golden yellow / brown

Humidity level : 11% – 15%

Stiff and resilient natural bristles ideal for brooms, brushes, and other cleaning tools. Eco-friendly and strong, trusted by manufacturers worldwide.

Made from high-quality coconut husk, our cocofiber offers exceptional tensile strength, elasticity, and durability.

Dimensions : 110cm x 70cm x 40cm

Weight : 90kg – 100kg (bales)

Colors : golden yellow / brown

Humidity level : 11% – 15%

A natural growing medium made from coconut husk dust. Excellent water retention, aeration, and used widely in horticulture, hydroponics, and soil improvement.

Made from high-quality coconut husk, our cocofiber offers exceptional tensile strength, elasticity, and durability.

Dimensions : 110cm x 70cm x 40cm

Weight : 90kg – 100kg (bales)

Colors : golden yellow / brown

Humidity level : 11% – 15%

Cocofiber is sun-dried directly under natural sunlight. This drying process is crucial to reduce the moisture level to an acceptable standard before being shaped into cocofiber bales.

Once dried, the cocofiber is compressed using a hydraulic pressing machine to form square-shaped bales. The final bale weight is approximately 90 kg – 100 kg and ready to be loaded into containers for export.

Cocobristle is selected from coarse coconut fiber. The bristles are carefully cleaned to remove dust and impurities to meet export quality standards.

fter cleaning, the bristles are trimmed to standard lengths (based on buyer requirements), then tightly bundled for easy handling and packing.

Raw cocopeat is washed thoroughly to reduce salt content (EC level) and remove impurities. It then goes through a filtering process to separate fine and coarse particles.

Once filtered, cocopeat is sun-dried to reduce moisture. Then it is compressed into blocks or bales, typically in 5 kg blocks or 25–35 kg compressed bales, ready for shipment.